Six Axis Fore OnRobot Force Sensor

Description

Kunwei sensor can be used to measure the force on the wrist of the robot in real time and realize the active force output control, which is equivalent to the human sensory nerve. It is a particularly important sensor in high complexity work, restrictive operation and coordinated operation. It can not only improve the flexibility of enterprise production, but also greatly reduce the cost of robot reprogramming caused by replacing product production line.

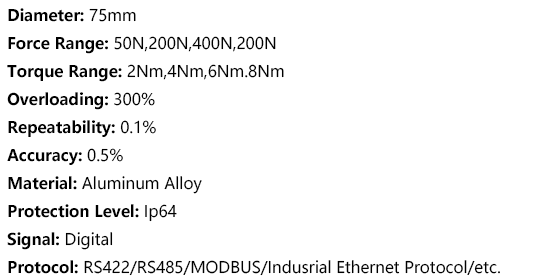

KWR75 series transducer is embedded in highly precision intelligent circuits, it is equipped with adapter flange, the customer could install flexibly according to their own needs. The series is available in several models, measuring range from 30N to 400N. The product uses digital signal ( serial port ) output by default, and can be embedded in analog signal data acquisition module to support analog signal ( such as 0-10V, 4-20mA, etc. ) receiving equipment ; and a serial port server device can also be used to support Ethernet-related equipment.

|

|

|

Model of KWR75

An application that we are seeing often with the sensor is the benchtest application. A robot is paired with a sensor and a gripper and is performing some cyclic action on a product. Where the sensor gets involved is when a given amount of force has to be applied on a device. The robot can apply a limited force that has been set by the programmer and it can also monitor this force. This means the product is tested at a given force and the force is monitored to see if there is any change in the behavior of the product.

Which Applications Requires Torque Readings

Hand-guiding would be an example that uses the torque information. Hand-guiding is the action of guiding a robot with your hands. This means you have to apply a certain amount of force on the tool to teach the robot a path, for example. As the force is applied on the tool (that is lower than the sensor), it creates a torque. This torque can be read in all the directions and the signal can be sent to the computer for analysis.

Which Applications Requires Both Force and Torque

Assembly tasks would be an example of applications that require both force and torque readings. In fact, in an assembly line, you can encounter different problems (misalignment, tight fits, force tests, etc.). All kinds of situations are present in these applications. You might combine your assembly with a bench test, so that you can test a given feature of your assembly, for example. Or, you can use it to teach your robot specific tasks like Dragging Teaching.

The versatility of the Six Axis Fore OnRobot Force Sensor translates into a wide array of applications across industries.

Automotive Manufacturing

In automotive manufacturing, precision is non-negotiable. The sensor’s ability to detect variations in force ensures that components fit seamlessly, reducing the likelihood of assembly errors.

Electronics Assembly

Delicate electronics components demand gentle handling. The Six Axis Fore OnRobot Force Sensor allows robots to navigate the intricacies of electronics assembly with the exacting precision required.

Pharmaceutical Production

Pharmaceuticals must adhere to stringent quality standards. By accurately detecting material properties, the sensor aids in quality inspection and packaging processes.

Food and Beverage Industry

Even in the food and beverage industry, where products vary widely, the Six Axis Fore OnRobot Force Sensor excels. It enables robots to handle products with the right amount of force, reducing waste and ensuring product integrity.

Integration and Implementation

Implementing the Six Axis Fore OnRobot Force Sensor into existing robotic setups is a streamlined process. OnRobot provides comprehensive support and resources to ensure a smooth integration. Calibration and configuration are facilitated, enabling organizations to harness the full potential of the sensor swiftly.

The Six Axis Fore OnRobot Force Sensor boasts a range of attributes that make it a coveted asset in the realm of robotic applications. As the name suggests, this sensor operates across six axes, delivering comprehensive data about forces exerted in multiple directions. This dynamic capability allows robots to sense even the slightest variations in force, providing a level of tactile perception previously unattainable.

The advantages of incorporating the Six Axis Fore OnRobot Force Sensor into robotic applications are profound and far-reaching.

Enhanced Precision in Grasping and Manipulation

The Six Axis Fore OnRobot Force Sensor allows robots to grasp objects with unparalleled precision. Whether it’s delicately handling fragile items or gripping irregularly shaped objects, this sensor enables robots to apply the optimal amount of force. This enhanced precision translates into reduced instances of damage during manipulation.

Accurate Material Detection and Quality Inspection

In industries where material properties and quality are of utmost importance, the Six Axis Fore OnRobot Force Sensor shines. Robots equipped with this sensor can accurately detect variations in material properties. This capability proves invaluable in quality inspection processes, ensuring that only items meeting stringent standards move forward in the production line.

Collaborative Workspaces Made Safer

Collaborative robots, or cobots, have revolutionized the way humans and robots work together. The Six Axis Fore OnRobot Force Sensor adds an extra layer of safety to these interactions. By perceiving unexpected forces, the sensor enables cobots to halt their movements instantly, preventing accidents and ensuring a safer working environment.

Adaptive Manufacturing and Assembly Processes

Manufacturing processes are rarely static. The ability to adapt to variations in materials, dimensions, and conditions is a hallmark of efficiency. The Six Axis Fore OnRobot Force Sensor empowers robots to navigate these variations seamlessly. From adjusting grip force during assembly to accommodating material deviations, this sensor ensures that robotic tasks remain accurate and efficient.

Data-Driven Insights for Process Optimization

Data is the driving force behind optimization. The Six Axis Fore OnRobot Force Sensor generates a wealth of data about forces encountered during robotic tasks. This data can be harnessed to identify patterns, anomalies, and opportunities for improvement. Organizations can fine-tune their processes based on these insights, enhancing overall efficiency.